QWIK-PURE: Challenges, breakthroughs and milestones in oil-water separation

The development of the QWIK-PURE by BEKO TECHNOLOGIES is a good example of how innovative ideas and overcoming challenges can lead to a successful product. The result is a completely new type of oil-water separator that perfectly meets the industry's requirements for safety, hygiene and operator comfort. During the field tests, the simple clean operation, the display of the residual capacity, the plannable service and the modular concept for growing along impressed.

In this article, our CTO Norbert Strack talks about the milestones in the development of QWIK-PURE and the challenges involved.

- Simplify handling and optimize filter performance for oil-water separation

The idea for the QWIK-PURE was born with the aim of simplifying the handling of an oil-water separator, in particular the annoying change of cartridges or activated carbon bags, and optimizing the filter performance for the most difficult operating conditions. In addition, the device should be IoT-enabled, so that predictive maintenance is possible.

BEKO TECHNOLOGIES was the first manufacturer to integrate valve technology and electronics into such a device, turning a "dumb" filter vessel into an IoT-enabled system that relies on its own algorithm to control filtration. This, of course, increased the complexity as well as the development effort, making the project one of our biggest challenges.

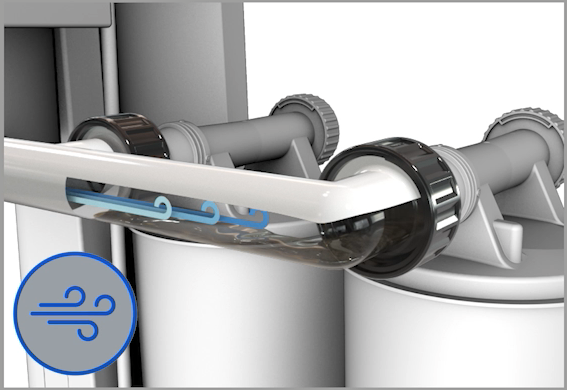

- Patented method of pressurizing the filter cartridges

The QWIK-PURE achieves its particularly high and safe filter performance through a patented process of pressurizing the filter cartridges. All components, including plastic injection molded and extruded parts, can handle this pressure difference under all environmental conditions, e.g. at high outside temperatures. The road to this goal was rocky, but it was successfully completed. BEKO TECHNOLOGIES thus has the first active oil-water separator on the market, and the manufacturing expertise gathered here can also be put to good use in other projects.

The challenges in developing the QWIK-PURE were enormous, but the result is worth all the effort. BEKO TECHNOLOGIES was able to develop a unique solution that has proven itself in numerous field tests under sometimes adverse conditions. The exceptionally good feedback from the first users and operators was a milestone in the development of the QWIK-PURE. When you manage to combine so much customer benefit in one product, it feels great.

- Cellulose fibers and sizing materials are no problem for QWIK-PURE

With such a radically new product, we placed great emphasis on testing.

During the two and a half years of field tests, we received positive feedback from pilot customers much faster than expected. Particularly impressive was the feedback from a user in the paper industry, where cellulose fibers and adhesive materials had previously been a major problem for condensate treatment. The customer subsequently wanted to order the QWIK-PURE immediately.

The training sessions showed that the QWIK-PURE convinces with many unique selling points. Each participant had a different focus. While the convenient and clean exchange of cartridges was particularly important for the service technician, the simplified stock-keeping and logistics were what counted for the dealers: only one cartridge format for all device sizes. The modular concept enables the sales department to offer the customer a solution that simply grows with future plant expansions.

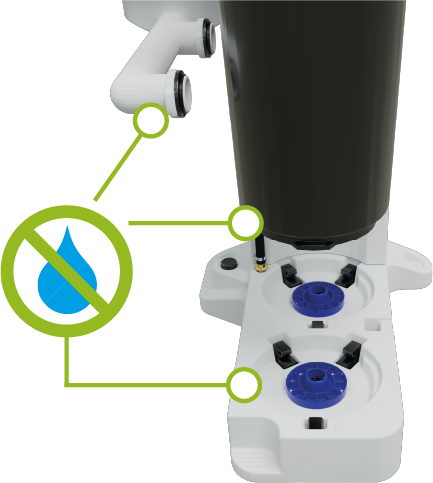

- Safety: No contact with contaminated filter material and ergonomic operation

The customers emphasized the importance of safety in two aspects: the protection of the environment from the discharge of oil and the protection of the users who will never again come into contact with biologically contaminated filter material. This is the "safe" in the QWIK-PURE product slogan "safe-clean-modular" and at the same time an important contribution to counteracting the shortage of skilled workers and offering potential applicants the best working conditions. With the QWIK-PURE oil-water separator, BEKO TECHNOLOGIES customers are not only using a sustainable product, but also an ergonomic one that protects the health of the workforce and makes everyday work easier thanks to its tool-free and simple operation. The QWIK-PURE thus fits perfectly into our series of sustainable products. Sustainability has been our DNA for more than 40 years. Back then, a new era was ushered in with the development of the BEKOMAT, the first electronically level-controlled condensate drain.

Customers are enthusiastic about the fact that their systems can grow with them thanks to the modular concept. Anyone who can assemble the shelving of a well-known Swedish furniture store is clearly qualified for the QWIK-PURE. Both initial installation and modular expansion can be performed without tools.

- Plannable service for oil-water separation

The QWIK-PURE control permanently displays the available residual capacity and has a special algorithm that takes into account a wide variety of influencing variables, such as the duration of the respective discharge process, the number of cartridges installed as well as the discharge processes that have already taken place and the time that has elapsed since the last change. By combining user care and device function, the environment is protected and the customer can avoid recourse claims.

The operating principle of the QWIK-PURE rules out "overflow", which is occasionally observed with oil-water separators in the industry. Thus, oil can no longer get into the wastewater - a decisive step for environmental protection.

The high filter performance of the QWIK-PURE ensures incomparably low material usage compared to the amount of condensate filtered. As a result, the QWIK-PURE sets new standards in the area of material utilization. It also avoids a lot of packaging and cleaning material that would otherwise have to be disposed of as hazardous waste. And another advantage: The QWIK-PURE eliminates the need for disposable gloves.

For me personally, the development of the QWIK-PURE was a highlight. We completely rethought the function of the oil-water separator and brought together creative minds from different fields to do so. We are particularly proud that we applied agile "design thinking" for the first time at BEKO TECHNOLOGIES. The team's many good ideas showed us that this modern method works and helped us develop a sustainable product.

Of course, there is always potential for further improvements in QWIK-PURE. But for the time being, our team's focus is on establishing the product on the market and delighting our customers.

And who knows, maybe in the future there will be more innovative products from BEKO TECHNOLOGIES that revolutionize the industry. We are always open to new ideas and challenges and look forward to providing our customers with clever solutions.

Overall, we are very proud of the QWIK-PURE and our team's achievement in developing and launching this game-changer. We are sure that it will play a major role in the industry and help many users to optimize their processes and make them more efficient.