DRYPOINT RA III: The powerhouse among refrigeration dryers

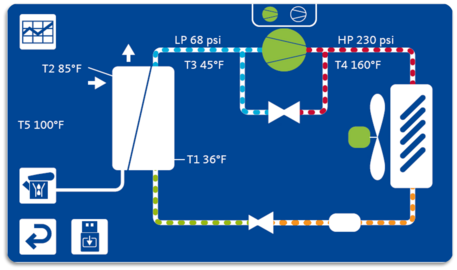

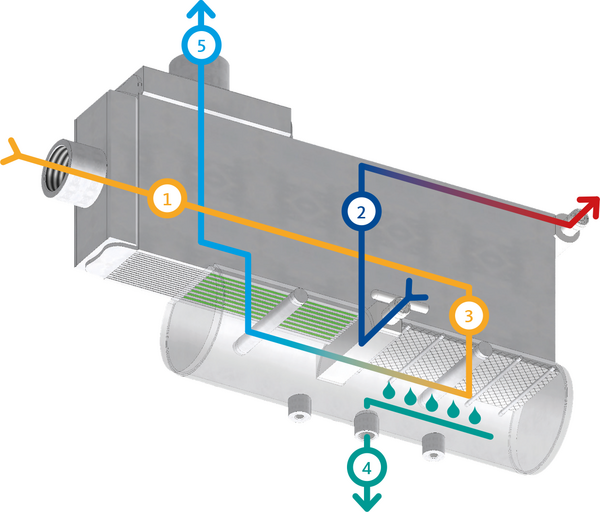

Elevate your compressed air treatment with the DRYPOINT RA III – an embodiment of inspiration, innovation, and conviction. BEKO TECHNOLOGIES is pioneering new standards in user-friendliness, reliability, and efficiency with this cutting-edge refrigeration dryer. Featuring an innovative heat exchanger design, a patented hot gas bypass valve, a stable dew point, and the integrated BEKOMAT condensate drain with zero compressed air loss, the DRYPOINT RA III represents a new era in advanced refrigeration dryers. The modern design with rounded corners not only adds a contemporary touch but also facilitates a compact and space-saving installation.

Why Choose the DRYPOINT RA III?

- Wide Model Range: From 20 m³/h to an impressive 3,000 m³/h, we offer the perfect solution for your needs.

- Intuitive IIoT-Enabled Controls: Our user-friendly controls with Industrial Internet of Things (IIoT) capabilities make monitoring and managing the drying process effortless.

- Innovative Heat Exchanger Design: Redefining efficiency with a unique design that minimizes pressure loss.

- Energy-Saving Compressors: Optimal compressor sizing ensures energy-efficient performance.

- Microchannel Condenser and Hot Gas Bypass Valve: Our special technologies guarantee outstanding performance.

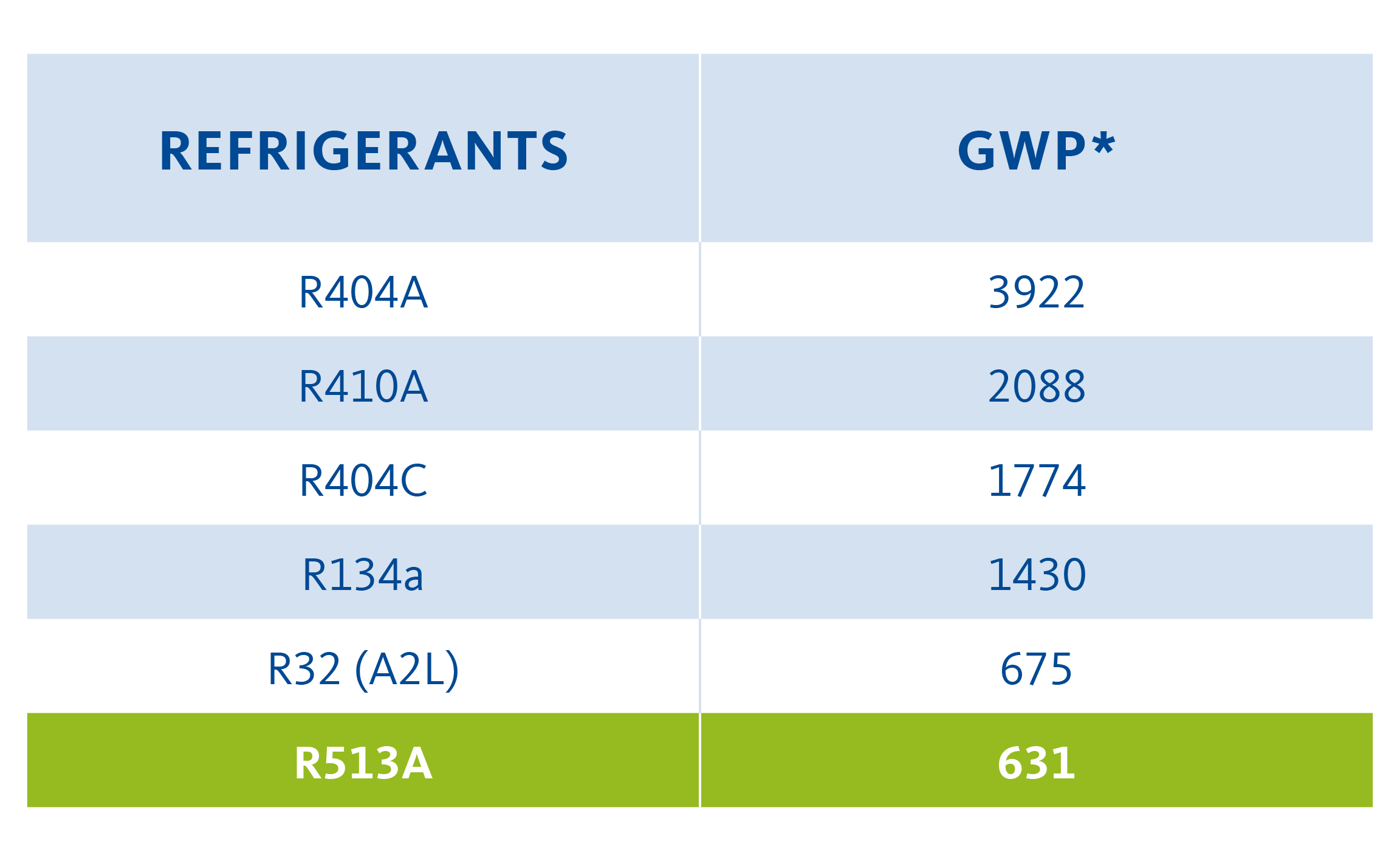

- Environmentally Friendly Refrigerants: Contributing to a sustainable future with ozone- and environmentally-friendly refrigerants (R513A).

- Compact Design: Space-saving and easily accessible – ideal for efficient service.

- Integrated BEKOMAT Condensate Drain: Ensuring smooth and reliable condensate removal.