- Precise oil vapour detection using high-precision PID sensor technology

- Reproducible accuracy of the oil vapour measured values due to reference gas generation (catalyst principle)

- Automatic monitoring of reference gas and sensor electronics

- Recording of all data in the integrated data logger METPOINT BDL

For mobile and flexible analysis of compressed air

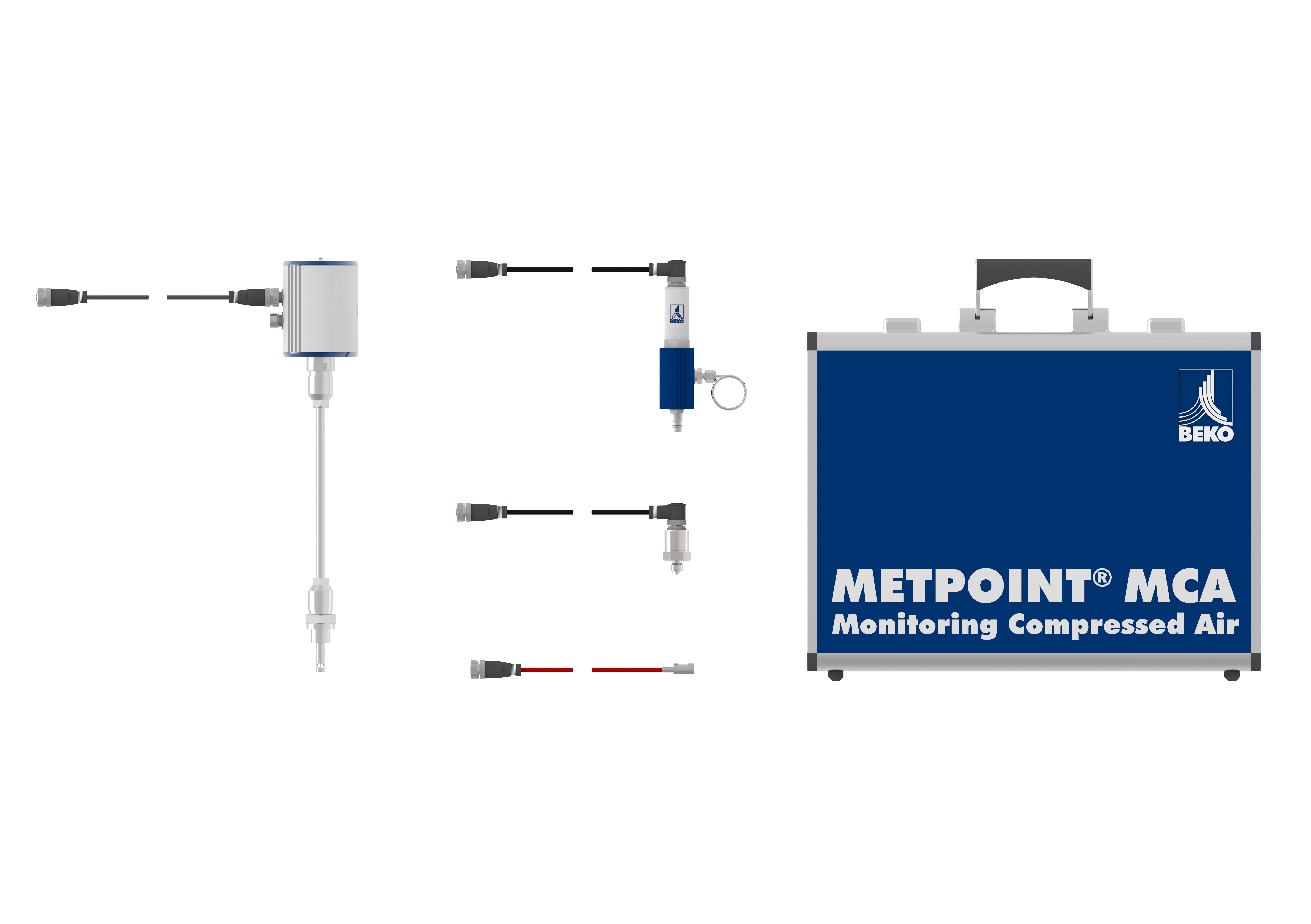

Continuous monitoring is essential for the functioning of your compressed air system. However, measurements may be necessary at locations where no stationary measuring equipment is (yet) installed. The METPOINT MCA ("Measuring Compressed Air") is a mobile and flexible solution for these situations.

The monitoring system (METPOINT OCV compact) was developed for measuring hydrocarbon vapours and gases in compressed air applications. The detection levels are as low as one thousandth mg/m³ of residual oil content and are executed continuously in ongoing operation. Short measuring intervals enable the rapid and reliable display of even the smallest of changes. This provides you with certainty about the residual oil content of your compressed air as an important element of your process reliability at all quality-critical points in the plant. The measurement data can be utilised for documenting the compressed air quality and for identifying contamination sources.

Modular adaptation to your individual requirements

The METPOINT MCA mobile measuring unit is available in various equipment variants (MCA O, MCA OP, MCA OS, MCA OPS). With all variants, the residual oil content of the compressed air can be measured and evaluated and documented via the integrated data logger.

The P option of the METPOINT MCA is additionally equipped with a high-precision particle counter in order to be able to detect even the tiniest of solids down to 0.1 μm in size. The flawless function of the filtration elements installed in the compressed air system is monitored and any filter perforations recognised immediately.

The S option has additional sensors in the case for recording humidity, volume flow, pressure and temperature and includes accessories. Recognise potentials for saving, optimisation of energy efficiency and quality. Identify the weaknesses in the compressed air system.

Measured Values

| MCA O | MCA OS | MCA OP | MCA OPS | |

| Residual oil content (oil vapour) [mg/m3] | x | x | x | x |

| Particle concentration [cts/m3] | x | x | ||

| Pressure dew point [°Ctd] | x | x | ||

| Temperature [°C] | x | x | ||

| Relative humidity[%] | x | x | ||

| Volume flow compressed air | x | x | ||

| Operating pressure [bar(g)] | x | x | ||

| Gas velocity compressed air [m/s] | x | x |

Configuration Variants

The equipment variants can be combined according to individual requirements. Check your complete compressed air system for oil vapour and find out where more intensive treatment is necessary – with our mobile measuring and analysis unit METPOINT MCA. With additional measuring method depending on requirements and option selected.

Overview of Advantages and Facts

- High-precision measuring methods from the proven METPOINT portfolio

- Measuring range oil vapour from ≤ 0.01 ... 2.5 mg/m³

- Pressure range from 3 ... 16 bar

- Can be used directly because supplied completely assembled

- Easy-to-read 7" touch display for visualization of measured values and easy configuration

- Sturdy aluminium frame with lockable wheels

- Easily accessible compressed air connection

- Common power supply with main switch

- Cover plate for protection during transport

- Flexible use at different locations

Do you have questions about the best way of processing your compressed air?

You want your compressed air system to work more efficiently and use less energy? There are problems with the continuous supply of compressed air? Pressure does not remain stable or the volume is not sufficient? Is your compressed air too humid, too cold or does heat cause operating problems? Are there rejects due to poor quality caused by contamination?

We have the answers! We offer efficient solutions for any type of processing chain. Please contact us with your queries. We would be delighted to tell you more about our condensate treatment, filtration, drying, measuring and process technology, and our comprehensive services..

Downloads